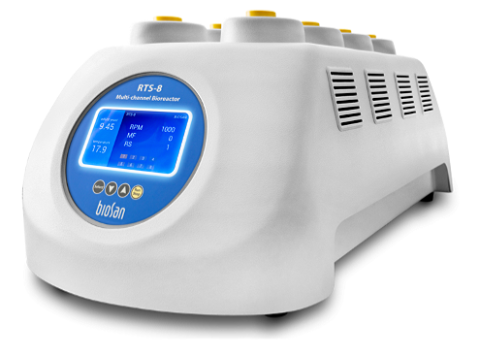

Multi Channel Bioreactor RTS-8

RTS-8 uses the patented ReverseSpin® technology. This is an innovative and energy-saving stirring technique that results in highly efficient mixing and oxygen supply for aerobic cultivation.

By rotating the Falcontubes around their own axis and changing the direction of rotation, the cell suspension is optimally mixed.

In combination with near-infrared optics, it is possible to measure the kinetics of cell growth non-invasively in real time.

Applications

- Fermentation real time growth kinetics

- Clone candidate screening

- Protein expression

- Temperature stress and fluctuation experiments

- Media screening and optimization

- Growth characterization

- Inhibition and toxicity tests

- Strain quality control

- Initial bioprocess optimization studies

Bioreactor RTS-8

- Parallel cultivation enables to save time and resources for bioprocess optimization

- Individually controlled bioreactor accelerates optimization process

- Possibility to cultivate microaerophilic and obligate anaerobic microorganisms (not strict anaerobic conditi ons)

- Reverse-Spin® mixing principle enables non-invasive biomass measurement in real time

- Near-infrared optical system makes it possible to register cell growth kinetics

- Free of charge soft ware for storage, demonstration and analysis of data in real time

- Compact design with low profile and small footprint for personal application

- Temperature control for bioprocess applications

- Active cooling for rapid temperature control, e.g. for temperature fluctuation experiments

- Task profiling for process automatization

- Cloud data storage to remotely monitor the process of cultivation while at home or using a mobile phones

Software Features RTS-8

- Real-Time cell growth logging

- 3D graphical representation of OD or growth rate over time over unit

- Pause option

- Save/Load option

- Report option: PDF and Excel

- Connect up to 12 units (recommended) simultaneously to 1 computer

- Remote monitoring option (requires internet connection)

- Cycling/Profiling options

- User manual calibration possibility for most cells

Benefits RTS-8

RTS mixing principle has a number of advantages, e.g. automatic balancing, defoaming single-use, etc., but one of the more important points is that, due to the individual rotation principle and thermostating of each bioreactor tube, different conditions for supporting the temperature (from 4 to 70°C) and aeration conditions can be applied (from anaerobic to aerobic).

| Light source | Laser |

| Measurement wavelength (λ) | 850 ± 15 nm |

| Measurement range | 0 – 100 OD600 |

| E.coli factory calibration measurement range | 0 – 50 OD600 |

| S.cerevisiae factory calibration measurement range | 0 – 75 OD600 |

| Achievable user calibration measurement error (range 0.1-6 OD600) | ± 0.3 |

| Achievable user calibration measurement error (range 6-50 OD600) | ≤ 5% |

| Achievable user calibration measurement error (range 50-75 OD600) | ≤ 10% |

| Measurement periodicity per hour | 1 – 60 |

| Temperature setting range | +15°C bis +60°C |

| Temperature control range | 15°C below ambient up to +60°C |

| Temperature stability | ±0.3°C |

| Sample temperature accuracy (20°C – 37°C) | ±1°C |

| Tube sockets | 8 |

| Sample working volume range | 3 – 50 ml |

| Speed control range | 150 – 2700 rpm |

| Reverse spin time setting range 150-250 rpm | 0 sec |

| Reverse spin time setting range 250–300 rpm | 2 – 60 sec |

| Reverse spin time setting range 300–2700 rpm | 0 – 60 sec |

| Display | LCD |

| Minimum PC requirements | Intel/AMD Processor, 1 GB RAM, Windows Vista/7/8/8.1/10/11, USB 2.0 port |

| Dimensions (W x D x H) | 350 x 690 x 300 mm |

| Weight | 20 kg |

| Internal power supply | AC 230 V 50 Hz |

| Power consumption | 3.15 A / 500 W |